The Future of Gasification: Trends and Innovations

In the quest for sustainable energy solutions, gasification has emerged as a versatile and promising technology. By converting organic materials into valuable energy resources, gasification offers a pathway towards cleaner and more efficient energy production. As we look ahead to

Innovating Towards Sustainability: Waste to Energy System Secures Patent for Downdraft Gasification

In a world where the need for sustainable energy solutions is more pressing than ever, innovation plays a pivotal role in driving change. Recently, a breakthrough in renewable energy technology has captured attention as Waste to Energy Systems, LLC has

Waste water treatment plants are using gasification for energy

Since the 1970's, humans have treated wastewater to protect human and ecological health from waterborne diseases. There are approximately 14,000 waste water treatment plants in the US alone and they generate over 13.8 million tons (dry weight) of sludge annually.

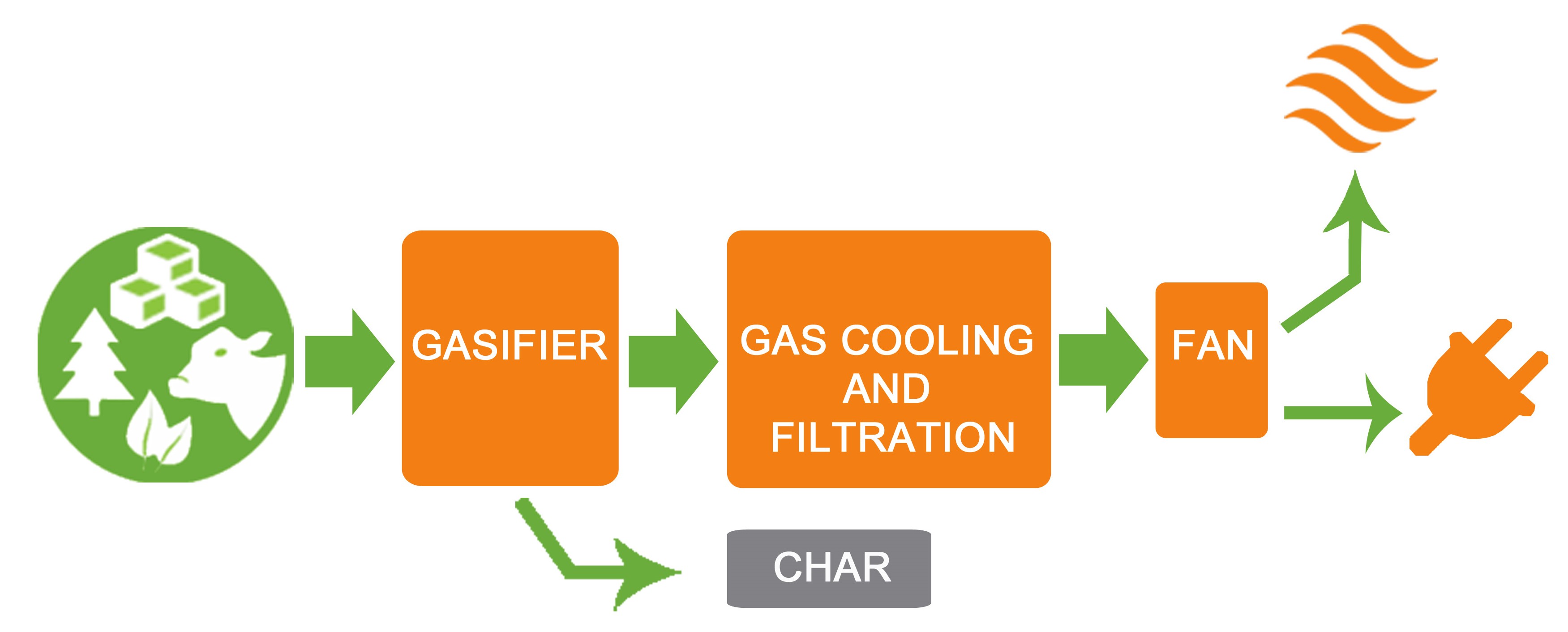

Types of Gasification: Which is the best process?

There are several types of gasification available on the market today. But not all are created equal. The right process for a project depends on several variables including the type of waste being processed and the customers needs (heat and/or

Medical Waste and Gasification: The COVID-19 Waste Solution

With the number of patients from the COVID-19 pandemic in the millions, an increase in the amount of medical waste laden with the virus is guaranteed. In Wuhan alone, where the coronavirus first emerged, officials not only needed to build

Biomass Gasification gets a Thumbs Up in Recent Study

Biomass gasification is quickly gaining popularity as companies like Waste to Energy Systems continue to make advancements. A recent article on Bioenergy News website discusses the benefits of this technology in their article "Global researchers give thumbs up to advanced

EPA Addresses Potential of Biomass

Blogger's Note: The Clean Power Plan was implemented on August 3, 2015 by the EPA. The Clean Power Plan finalized new rules, or standards, that will reduce carbon emissions from power plants for the first time. As a result, new focus is

Biomass Gasification- A Promising Energy Option

The four hundred year old technology of Gasification is finally getting some well deserved attention in the Alternative Energy world. With companies like Waste to Energy Systems fine tuning the gasification process, biomass as a fuel source for the process will continue

WES Team Attends National Bioenergy Day Conference

As a testament to the growing popularity of biomass and bioenergy, October 21st marked the 3rd annual National Bioenergy Day. Over 60 organizations across 24 states, spanning from the west coast to east coast all the way up to Canada,

Waste To Energy System’s CEO Featured In Entrepreneurship Magazine

Our CEO, Richard Woods was featured in the Entrepreneurship Issue of the Greater Baton Rouge Business Report Magazine. The article highlights his R&D efforts for our system and his future goals for both of his companies, Albany Woodworks and Waste